© This presentation is Copyright by Professor Paul G Ranky, PhD, Full Tenured Professor at the Department of Mechanical and Industrial Engineering, and the IS/IT Program at NJIT, USA. The URL: http://www.cimwareukandusa.com/All-Green/Ranky-GreenEngineering.html

iSEE:Green, intelligent Sustainable Enterprise Engineering, Green Engineering Methods, Tools and Technologies Teach Us How to Simultaneously Increase Quality, Reduce Cost, Stay Sustainably Green Compliant, Reduce Environmental Impact and Eliminate VERY Costly, Non-sustainable Safety and Quality Related Recalls...

Professor Ranky's iSEE:Green Sustainable Green Engineering Seminar Schedule:

Please note, that other dates can be added. Please contact Professor Ranky by email, or telephone: (201) 493 0521

Welcome!

By explaining iSEE:Green (Sustainable Enterprise Engineering) green principles, methods, tools and technologies, my goal is to help you to improve your sustainable, quantifiable lean and green design and manufacturing activities in terms of engineering a product, a process and/or a service system in various industries and countries around the world.

The fundamental purpose of the greening effort is to help to increase quality of life. Furthermore, it is to improve the quality of green compliant products and processes, and simultaneously reduce cost, pollution, the carbon and the environmental footprint of all product design, manufacturing and related activities. This includes raw material processing, warehousing, transportation, logistics, remanufacturing, recycling, and even reuse.

My hope is that we can all stay compliant with USA, European, and other valuable international 'green' principles and laws that govern global trade and supply chains, whilst maintaining crucially important IP (Intellectual Property) rights.

What makes green design and manufacturing (in other words green engineering) very exciting, is that it is an interdisciplinary subject. It should attract a flexible person with an open mind, who is ready to think laterally, structure, reason and integrate quality information, and then turn it into new knowledge to help mankind and all living entities on our planet.

Consider the fact that factory pollution created in one continent can now be measured in another... therefore it is not a local issue anymore... pollution and toxicity changes everybody's life on Earth... not just those who are polluted, but also those who are polluting!

Maybe it is time for mankind to wake up and realize that we are all in the same boat and it is our common interest to change our polluting, toxic products, processes, factories and systems for sustainable, energy efficient green solutions... and as we'll see later in this presentation, greening makes excellent businees sense too.

The other very important driving force towards green, is that governments enforce compliance and IP, and consumers in the USA, as well as in Europe, and increasingly in Asia (China, Hong Kong, Taiwan and Japan) demand green products, made in non-polluting sustainable green factories...

Consider this interesting fact: over 92% of young graduates in the USA want to work for a 'green' enterprise... also, 9 out of 10 new venture capital applications in California relate to some kind of greening invention... and this is just the beginning.

Greening an dsustainable engineering will become a bigger revolution than what the Internet has created for all of us!

In a free society consumers have a lot of power, and can change entire industries by purchasing only environmentally friendly, green products... designed and made in green, sustainable factories... Shouldn't we all be ready to drive this major transition?

Welcome to my green engineering world (above and below the ocean... ) As a PADI certified Rescue Diver, I do care about green products, processes, factories and schools, as well as eco-tourism and the condition of the reefs.

Paul G. Ranky, PhD

Full Tenured Professor

Registered Chartered Professional Engineer

Professional Consultant (with over 30 years of professional consulting experiences in Europe, USA, and Asia)

Member of the American Society for Quality (ASQ), Audit Division and Lean Enterprise / Advanced Manufacturing Division, IEEE Green Engineering Editor. Also member, or former member of ISPE, International Society of Pharmaceutical Engineers, USA, ASEE, American Soc. of Engineering Educators, IEEE (USA), Institute of Electrical and Electronic Engineers, IEE / IET(UK), Institute of Engineering and Technology, FEANI(Europe), SAE(USA), Society of Automotive Engineers, PMI(USA), Project Management Institute.

Department of Mechanical and Industrial Engineering, and the IS/ IT Program at NJIT

New Jersey Institute of Technology, The Public Research University of New Jersey, University Heights, NJ 07102, USA

More about NJIT, New Jersey, USA

You can email me at cimware@mac.com or paul.ranky.njit.edu@mac.com.

More about the Professor’s past and current research work and background at: http://www.cimwareukandusa.com/aboutpgr.htm

More about the Professor’s publications at: http://www.cimwareukandusa.com

Please note, that this document will be updated. Also note, that there are links from this document to other resources. These links worked at the time of writing, nevertheless might be changed beyond my control. Please stay green and do not print this document. Email me and keep in touch! Thank you!

Contents:

In my presentation I talk about some useful generic analytical methods and computational tools, and apply them to solve specific real-world, practical greening challenges in industry and in R&D. We'll follow well known methods and teaching learning techniques, as well as some new 3D web-based solutions. (I agree with the old Chinese saying: Tell me and I will forget, show me and I will remember, involve me and I will understand, take one step back and I will act...)

This is the broad outline of my presentation:

Sustainable lean and green methods are used in all areas of engineering and IS/IT, including product and process design, control, fabrication, test, assembly, disassembly, transportation, warehousing, and even in remanufacturing, recycling and reuse.

As one can see from the above list, advanced, sustainable green engineering design and manufacturing is a huge and complex subject. Unfortunately there is no single differential equation to solve it all, and quite frankly none of us is an expert in all aspects of leaning and greening... because it is an interdisciplinary science and technology; BUT if we all try to do our best and continue to learn, explore and create, the world will be leaner and greener every day!

What is Green Design and Manufacturing Engineering Sustainability?

In terms of green engineering design and manufacturing sustainability we consider the following:

As Dr. Barbara Karn is a scientist in EPA’s National Center for Environmental Research and a regular Science Wednesday contributor states: 'I work with sustainability (and nanotechnology) most of the time and am comfortable with the 1987 Brundtland commission’s statement: “Humanity has the ability to make development sustainable to ensure that it meets the needs of the present without compromising the ability of future generations to meet their own needs.” But what does this have to do with true north? …and is there an “un-true” north?

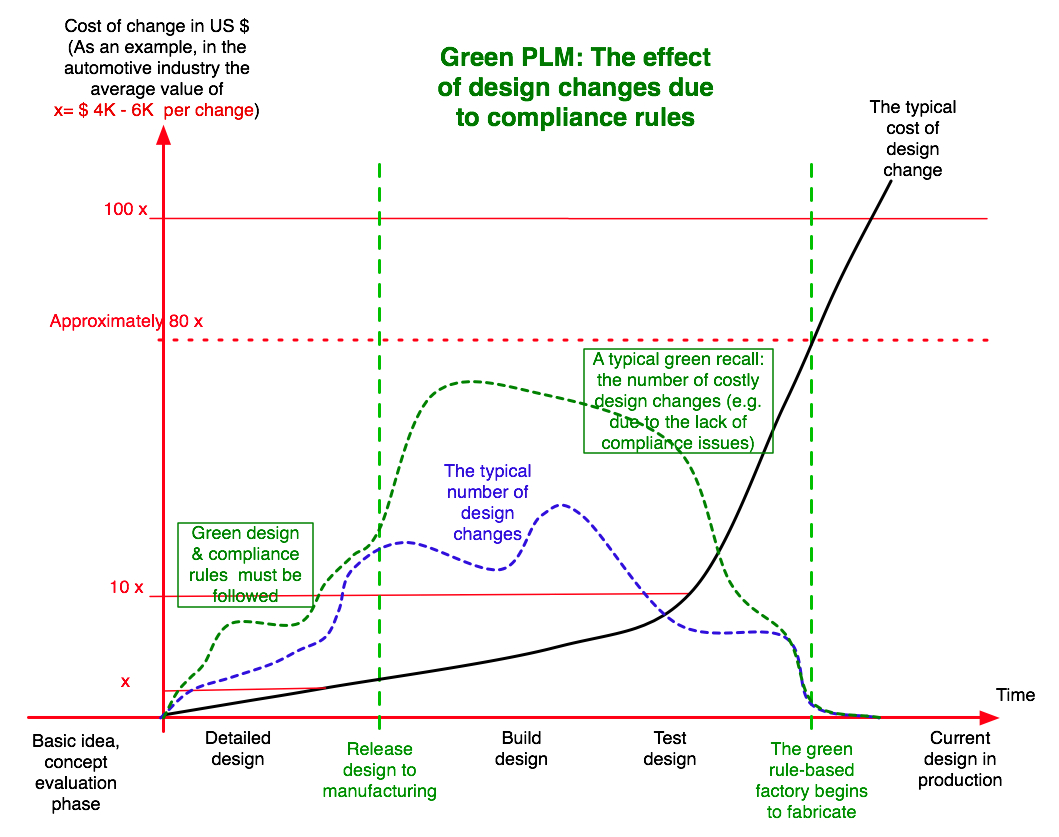

Focusing on sustainable design and green engineering, the diagram illustrates below, engineering design changes are not free... as a matter of fact, when the customers require eco-friendly green products, manufactured in green factories there will be lots of costly design and manufacturing process changes... if the greening focus comes in late, a major loss to all, in comparison to getting it green in the first place... (Note again, that greening products is essential: 92% of young USA graduates want to work for sustainable green companies... these are the future green customers and consumers who will purchase green products if they have a choice... and competition will create choices,)

What is Green PLM (Product Lifecycle Management)?

As we can see from the graph above, green design and manufacturing (with a strong green PLM focus) has impressive ROI (Return On Investment) and new revenue creation opportunities.

This is because of the following:

Sustainable, green engineering design and manufacturing are effecting every aspect of our life. This is because the climate is changing (ref. world climate projections and simulations). Since so many methods, processes, designs and systems have to be changed, this is only the beginning... this green revolution will be even bigger than the Internet revolution is. Greening has already attracted a wide area of research topics.

These are mainly non-traditional, interdisciplinary areas of research, emphasizing a systems approach to green design and manufacturing and related fields. Known research subjects include the following:

U.S. Makes Progress Toward Cleaner Air: National trends show improvements in the nation’s air quality...

WASHINGTON – The U.S. Environmental Protection Agency (EPA) is making the most recent data available on the state of the nation’s air quality. Air pollution impacts public health, the environment, and the Earth’s climate, and understanding these impacts are important priorities for the agency. EPA regulatory actions and voluntary efforts have led to cleaner cars, industries and consumer products, that in turn have contributed to improvements in the nation's air.

Since 1990, nationwide air quality has improved significantly for the six common air pollutants: ground-level ozone, particle pollution, lead, nitrogen dioxide, carbon monoxide, and sulfur dioxide. Emissions of toxic air pollutants, such as benzene, have declined about 40 percent nationwide between 1990 and 2005.

These reductions are helping to improve public health by decreasing the number of emergency room visits, respiratory illnesses, and premature deaths. Positive impacts can also be seen in the environment, with regional haze decreasing.

Despite this progress, about 127 million Americans live in counties violating at least one of the national air quality standards. The agency has taken recent actions to tighten air quality standards to help ensure improvements in air quality for everyone.

EPA’s most recent evaluation of air pollution, Our Nation’s Air, Status and Trends Through 2008, presents trends in air quality measurements, analyzes national emissions from key industrial sectors and takes a look at the relationship between air quality and climate change. (More information: http://www.epa.gov/airtrends)

In practice, in this presentation, just as in the real world, this means reorganizing / redesigning products and manufacturing processes, local and global supply chain processes to achieve environmental outcomes through, resource exchange, recycling, and energy reduction.

Green Economy: The Bottom Line...

Obviously when you are considering saving the environment and producing goods that truly create a sustainable quality life, the first thing opposition claims is, that 'OK, but it must be very expensive!'.

Well, in the long term definitely not... and of course how do you price saving human lives, elderly support and hospitalization expenses, toxic waste cleanup costs, or recalls, the greenhouse effect, and many others... you cannot and you should not focus on short term gain at human expense... the world has grown up; this is the Internet-age and information travels faster than ever before... in other words there are less and less secrets about toxic waste and long term health effects often covered up by powerful corporations and corrupt media. (Please note, that not every corporation produces toxic waste, and not every media organization is corrupt!)

In terms of some facts, this is what the Aberdeen Group has found (February 2008 Report on Green Initiatives: Lowering costs and Increasing Efficiency..., USA):

Of the surveyed financial executives 39% found green initiatives defensible from the ROI (Return Of Investent) point of view,

These figures are even more important, considering that in the data storage and server market, an important IT / IS aspect of advanced manufacturing, the growth rate in the USA is 27% (2008 figure) annually, whilst the data center energy consumption growth rate is 40% annually (2008 figure).

The Gartner Group finds, that the 'upward-spiraling infrastructure demands and increasing energy costs mean, that the energy proportion of IT costs could double by 2012.'

This calls for advanced real-time energy and reliability monitoring and modeling tools, that can change the nature of data centers from static entities to dynamic 'living organisms' during the next five or more years.

They also found the following:

Some more statistics on financial aspects (Ref.: the Gartner Group, USA):

The key to a meaningful ROI calculation here is to be able to measure infrastructure efficiency at all levels and then add up all numbers for an entire site, as well as for the entire supply chain. Easier said, than done, nevertheless the energy savings are typically around 21% (Ref.: the Aberdeen Group) and even the reliability went up in 58% of the best class companies.

It has also been found by the Aberdeen Group of surveys, that these are the key efficiency enhancing technologies:

Clearly, since every advanced manufacturing company is an advanced IT / IS system too, these data reflect the huge savings as well as gains the greening process can create!

More Financial News on Renewable Energy...

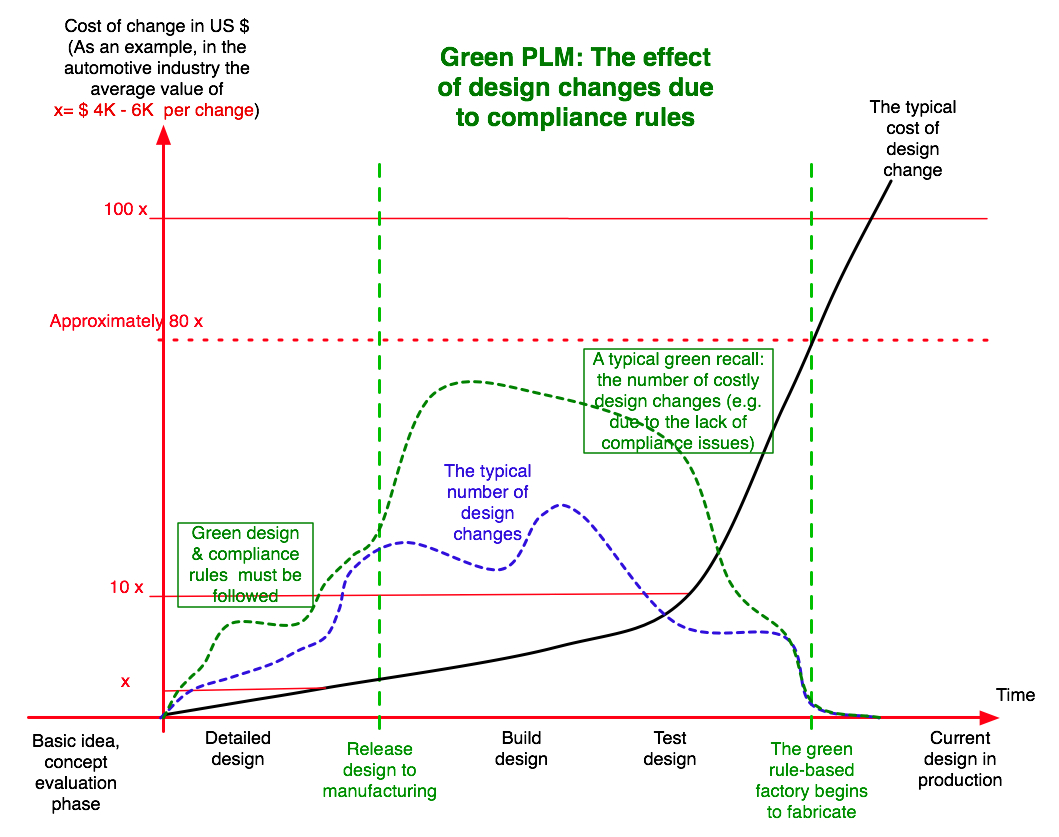

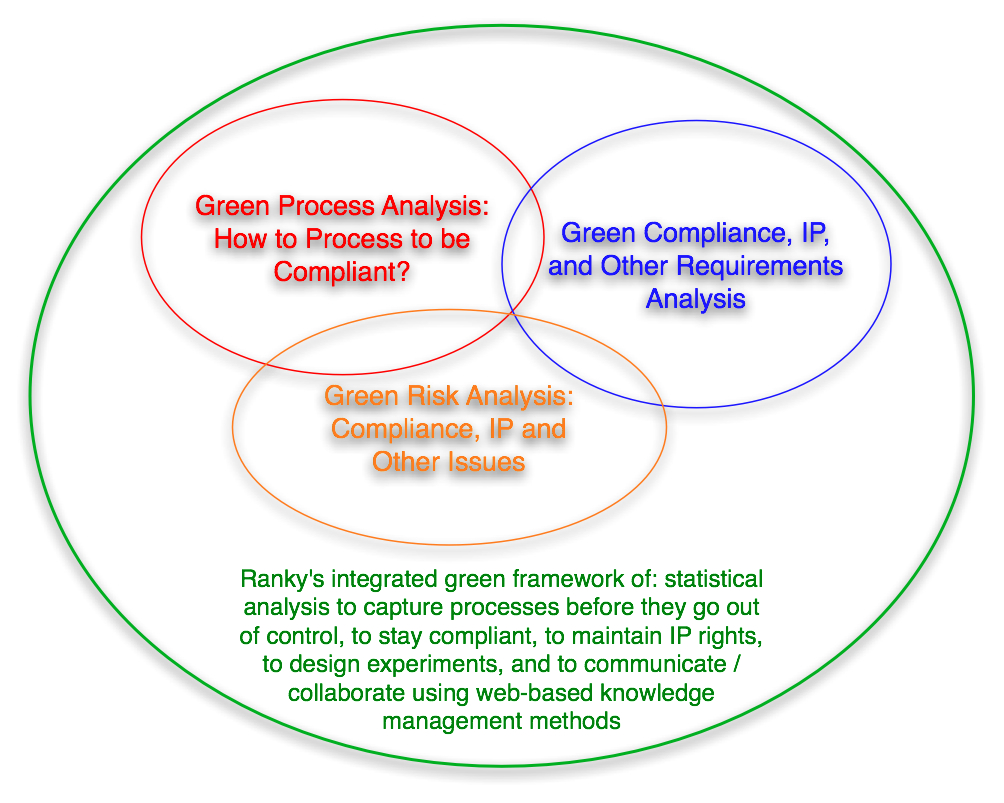

The cost figure below illustrates the huge cost saving opportunities when going green... keep in mind, that in a free economy customers decide what they want to purchase... and the customers in the USA and in Europe are already demanding green products... in large numbers! .., and this will spread around the world fast, subject to choice!

As we have seen in the past, recalls due to toxic paint in toys, oil spills, toxic chemicals in factories, in milk, and many other challenges in many industries were extremely expensive... and forced major product redesigns; this time with a green focus... but why not in the first place? Consider the huge savings and the competitive advantage when designing and manufacturing following sustainable green rules... As you can see below, the potential for product / process life-cycle cost savings is the largest at the basic idea / conceptual phase. This is the time when we must focus on greening more than ever before!

Greening Engineers...

There is something else: the world is short of 'greening engineers'... we need more greening experts... just one specific example:

Ann Arbor Buisness Review in Michigan (USA) Business Innovation blog, Nathan Bomey wrote, "The electrification of the vehicle" needs a "new kind of engineer." This "is such a brand new challenge that it should come at no surprise that the educational system has yet to produce a meaningful number of engineers who can handle these challenges."

The reason why GM must work "around the clock to create the Chevrolet Volt" is because it "hasn't been done before.

" Bomey argued that the "wealth of engineering talent" in southeast Michigan is "a key reason why the engineering services and advanced manufacturing sectors are likely to play a critical role in Michigan's economic turnaround."

Yet, "automotive executives say they are having a hard time finding the kind of engineer that can handle the high-tech challenges presented by the rapid shifts in the industry."

China needs greening engineers / environmental engineers too... please read about some new developments in turning China into a greener place... as William McDonough, chief green architect for China states:

' If China carries on with their current rate of urbanization, they'll be left in 2020 with only 20% of their current farmland'... and feeding about 1.5 bllion people is not a small task... (Ref.: http://www.pbs.org/frontlineworld/fellows/green_dreams/, and more here: http://money.cnn.com/magazines/business2/business2_archive/2006/11/01/8392027/index.htm)

The IEEE (USA) Reports the Following Important Facts (Ref.: http://newsmanager.commpartners.com/ieeetw/issues/2008-08-27/1.html)

Abundant, cost-efficient energy is the staff of life, economic life, that is.

Whether fired by fossil fuels such as oil, coal and natural gas, or in renewable, that is, sustainable forms, such as wind, solar and nuclear, power makes modern economies – and modern standards of living – possible.

Fossil fuels, however, are disappearing amid tremendous demand from both emerging and industrialized nations. Couple the supply-and-demand equation with the considerable environmental ramifications, and the burning of fossil fuels appears to be simply unsustainable.

A variety of data from around the world underscores the importance of solving the problem:

IEEE research showed that sustainable energy is a very hot topic, reflecting the general public's keen interest in the environment and renewable energy. More than 75 percent of respondents said they were interested in learning more about sustainable energy.

But did you know that:

I am pleased to state, that my own surveys in my undergraduate and graduate classes in NJIT indicate, that 100% of our students are very keen on greening! (This is based on a survey of my own students, about 250-260 students a year, over 90% graduate students at NJIT.)

Ranky's Greening Architectural Framework and Sustainable SEE:Green Process Plan...

The sustainable lean and greening process is a journey, not a destination. It is different for each corporation with some common continuous improvement requirements and risk reduction solutions all the way. It looks easy and simple, but it is very hard.

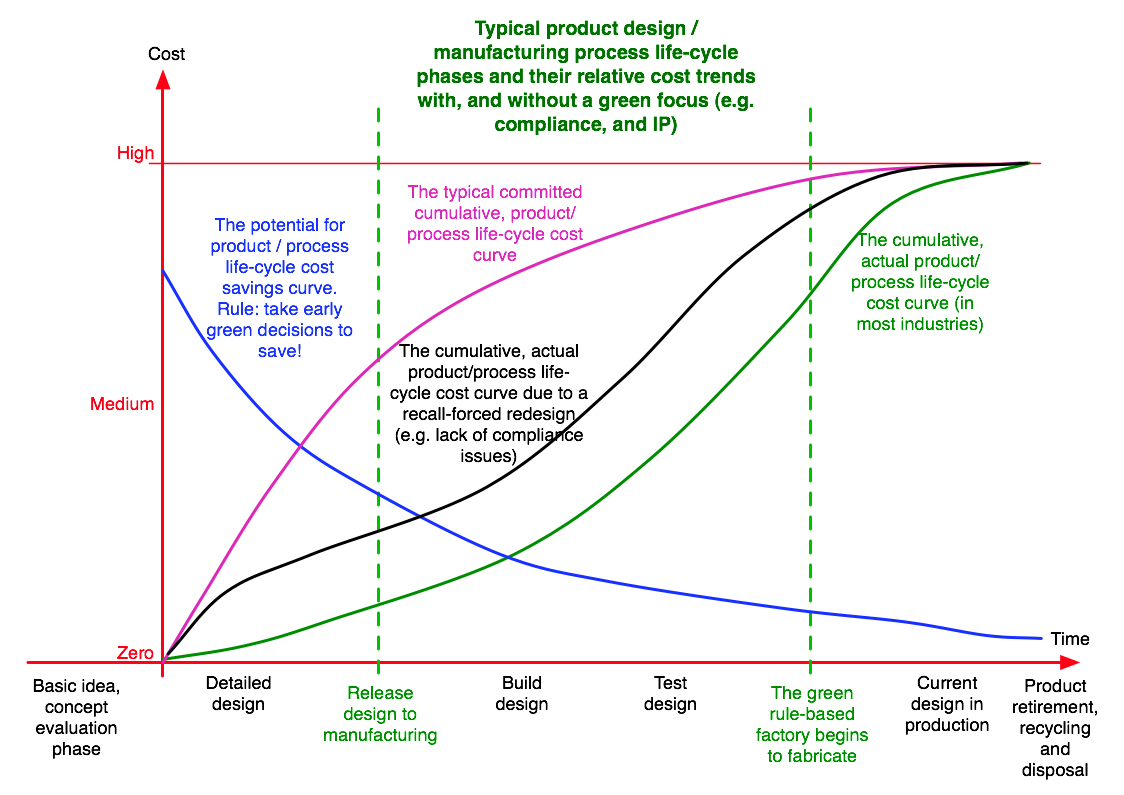

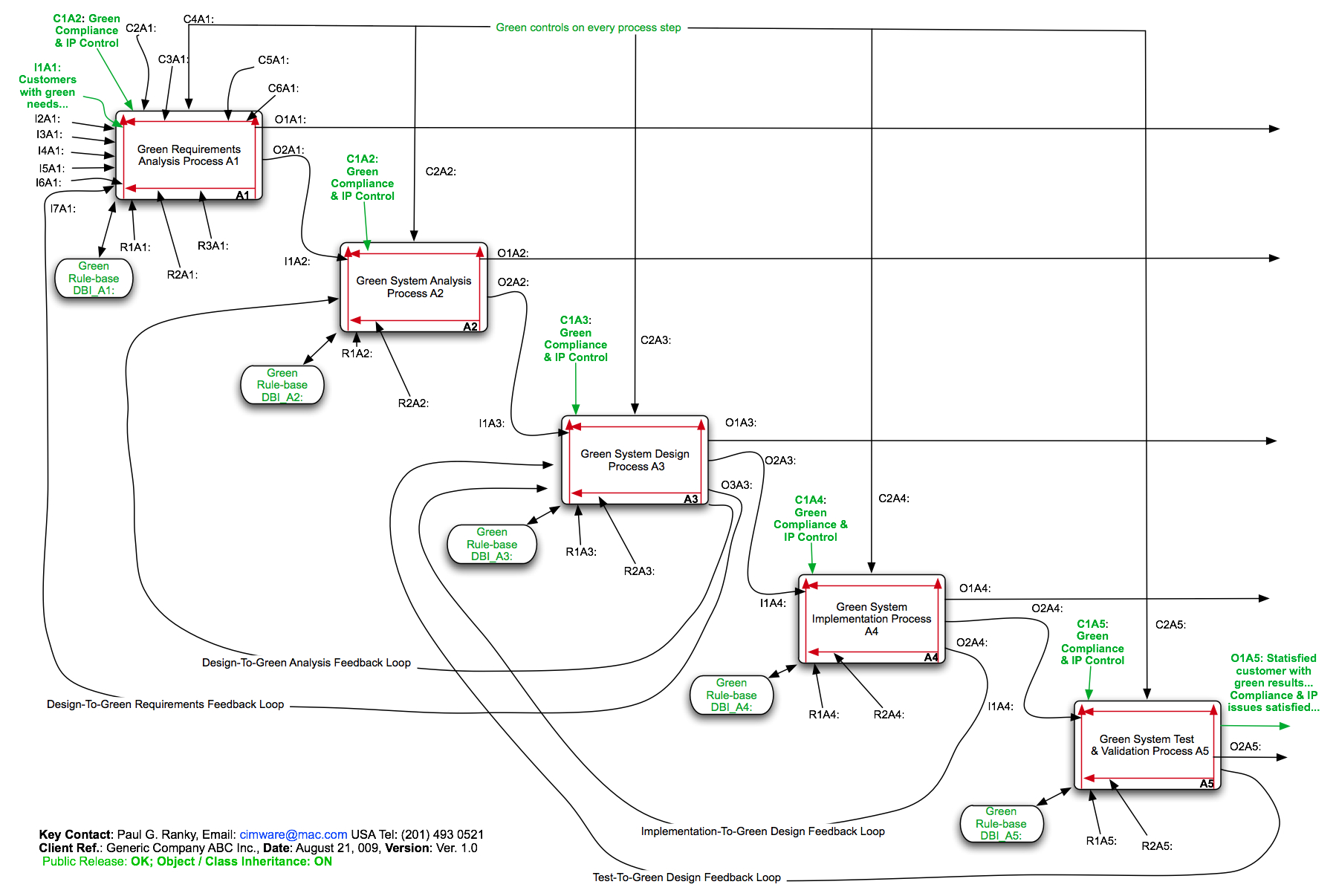

In this presentation we'll learn some professional object-oriented process modelling methods, that support the engineers and managers in their greening processes following international benchmarks and standards. By following our methods and tools individual processes can be evaluated and changed, if necessary, for green processes, based on customer requirements, and risk assessment using sustainability statistics.

The diagrams below show our overall greening systems architecture, as well as our macro level greening process flow, following a well established and validated lean six-sigma statistical quality framework.

...and my Generic Greening Process Plan... (more details on these methods and tools at: http://www.cimwareukandusa.com)

(Click on image to enlarge)

Examples of Greening Challenges and Use-Cases...

Greening products, manufacturing processes and service systems to make them green compliant for the USA, Euroean and many other industries, is not a simple task, nevertheless by following our lean six-sigma focused greening framework and methods we can identify the major process steps, that we need to analyze and fix, in terms of what the customers require, what risks they carry, statistically how they behave, and other aspects.

We show below an example, that has some greening challenges... this is only one of the many use cases and examples we discuss in this course in detail using digital interactive videos, real-world products, and 3D interactive multimedia.

(Just click with the mouse on the poster frame below. The 3D QuickTime application should run. Whilst holding down the mouse on the poster frame move it left and right to enjoy the 3D interactivity... Please note, that to run this example you'll need Apple's cross platform Quicktime player, FREE from the Apple web site www.apple.com. Please note, that at the time of writing these files will not work with any MS media player.)

The sustainable greening challenges above include material selection, lack of design for green manufacture, assembly, disassembly, demanufacturing and recycling processes...

We also show an impressive digital design and digital manufacturing simulation clip with simulated and dynamically accurate robots, done on Dessault Systemes' Delmia Package, a clip of Chongquing, a very polluted town in China, and to finish on a positive note, two beautiful clips, a healthy reef in the Caribbean where I dive a lot, and a beautiful ski resort, Killington in Vermont, USA, where I ski a lot... (Notice the incredible clear blue sky and visibility)... The choice is yours! Do you want to sleep in a toxic place or under the clear, blue sky? As you compare these 2D and 3D video objects you'll see what I am trying to achieve in terms of greening... Don't be depressed... these examples above represent typical greening challenges that can be solved!

And there is another interesting demo here: http://www.cimwareukandusa.com/RW-Street-PanoSiteNavig-Upload/RW-Street-PanoSiteNavigation-Map.html. This is a Panoramic Site Navigation map with Intarective Talking Panoramas and other objects. It is a good example (...really a mixed demo for a variety of audiences) the way ecology, environmental design, environmental responsibility, challenges and solutions, sustainability and other green engineering aspects could be introduced and educated at various levels.

Please note, that in Professor Ranky's full-length presentation several case studies are discussed in detail, and illustrated by analytical calculations, system models, as well as video media shot in the USA, Europe, China, the Philippines, the Caribbean, Palau and in Japan. (More videos, 3D multimedia eBooks and other details on these methods and tools at: http://www.cimwareukandusa.com)

To summarize, a successful green design and manufacturing, or R&D program in any organization will not only lower the impact on the environment, but should also contribute significantly to the bottom line via better energy, hardware and resource management.

Please note, that the 21st Century Engineer must be a professional information searcher, information and knowledge creator, as well as somebody who can reason over several different sets of information and then select the best possible solution path under constraints... You should be able to question, interrogate and take optimal decisions... not an easy task.

As Charles M. Vest, the President of the National Academy of Engineering, and the former President of the MIT, USA puts it (ref.: special guest editorial in the July 2008 Journal of Engineering Education, USA):

'The twenty-first century appears to be quite different, dominated by biology and information, but also by macro-scale issues like energy, water, and sustainability.

...My message here is that the twenty-first century will be very different from the twentieth. Engineering will be enormously exciting, and increasingly rich and complex in its context and importance.

As we think about the challenges ahead, it is important to remember that students are driven by passion, curiosity, engagement, and dreams.

Although we cannot know exactly what they should be taught, we can focus on the environment in which they learn and the forces, ideas, inspirations, and empowering situations to which they are exposed.

Despite our best efforts to plan their education, however, to a large extent we simply wind them up, step back, and watch the amazing things they do. In the long run, making universities and engineering schools exciting, creative, adventurous, rigorous, demanding, and empowering milieus is more important than specifying curricular details.

Nonetheless, I hope that those who design curricula, pedagogy, and student experiences will profitably contemplate the new context, competition, content, and challenges of engineering.'

Also he states:

'The National Academy of Engineering formed a committee of 17 amazingly creative and accomplished engineers and related scientists and medical experts and asked them to define several Engineering Grand Challenges for the decades ahead.

These challenges were to be such that accomplishing them would advance the human condition, and that the committee believed could actually be accomplished in the next few decades.

The committee proposed 14 unranked Engineering Grand Challenges:

• Make Solar Energy Economical

• Provide Energy from Fusion

• Develop Carbon Sequestration Methods

• Manage the Nitrogen Cycle

• Provide Access to Clean Water

• Engineer Better Medicines

• Advance Health Informatics

• Secure Cyberspace

• Prevent Nuclear Terror

• Restore and Improve Urban Infrastructure

• Reverse Engineer the Brain

• Enhance Virtual Reality

• Advance Personalized Learning

• Engineer the Tools of Scientific Discovery'

It is important to realize, that in the full length presentation, we introduce and discuss several of the above listed topics.

Brief Outline Of Professor Ranky's Full-length iSEE:Green Presentation

Please contact Professor Ranky by email, or telephone: (201) 493 0521

1. Introduction to SEE:Green, sustainable green design and manufacturing, and an overview of the subject. Definitions of important terms, such as sustainability, lean, green design, green manufacturing, and others. Introduction of lean as a data-driven, quantifiable optimization method. The key compliance requirements, and business drivers in the USA, in Europe and in Asia. Simultaneously acting constraints, including cost reduction, quality improvement and customer satisfaction requirements, compliance and IP issues, waste and risk reduction, carbon footprint reduction, energy reduction, lean and green sustainability, and others. Reasons why we must green our design engineering and manufacturing processes and factories on a global basis. The USA, the international scene, some predictable greening changes in the next 5 to 10 years, and these changes will effect you and me...

2. The 18 monozukuri principles to design and maintain sustainable green manufacturing processes with industrial examples and case studies captured in the USA, Europe, Japan, and China. Design For Environment (DFE), Design For Disassembly / Reuse rules and analysis, Disassembly Bill Of Materials (DBOM) analysis, the identification of toxic components, and others.

3. A set of iSEE:Green analytical methods, computational assessment and statistical tools for evaluating and designing green manufacturing sustainability processes, requirements, and risks. A carbon footprint assessment method and calculator, and an air pollution analysis method and tool. Product Life Cycle Assessment and Analysis standards and some tools. Interactive case studies from a variety of industries and countries.

4. The sustainable green manufacturing audit process, standards and compliance regulations, outcomes and assessment methods. How can we evaluate how lean and green are you? International green manufacturing standards and compliance. USA and EU compliance audit standards, and mainland China's recycling law, and what it means for sustainable green manufacturing processes, and export / import activities. Relevant ISO and USA standards, and compliance issues. International Chamber of Commerce trade rules and regulations, the Rio Declaration on Environment and Development. ISO 14001 and sub-standards. The European born Eco-Management and Audit Scheme (EMAS), and the International Organization of Standards 14001 (ISO 14001) and what it means for green manufacturing and international trade. Worldwide legislative activities and standardization. Interactive case studies from a variety of industries and countries.

5. Green materials, including biodegradable materials for green manufacturing processes. The European directive of the Restriction of Hazardous Substances (RoHS), WEEE: Waste Electrical and Electronic Equipment, Framework for setting up Eco-design Requirements for Energy-using Products (EuP), and related compliance issues and constraints that can make a product fail to enter the European market. New USA developments in 'greening' manufacturing and the world. USA compliance issues and restrictions. Also, how can we recycle and reuse materials and make the entire proces sustainable?

6. Industrial ecology to foster the co-operation among various industries whereby the waste of one production process becomes the feedstock for another... in a similar fashion to the way nature works... to identify ways for industry to safely interface with nature, in terms of location, intensity, timing, value added and non-value added processes, and others, to develop measurable and controllable indicators for real-time monitoring (e.g. 24/7 using sensor networks reporting over the Internet), to reduce the energy requirements when converting materials thoughout their entire life-cycle, and others. Long term land use planing within an ecological framework, that identifies, and protects environmental, cultural and historical values, as well as simultaneously becomes profitable for the community. Interactive case studies from a variety of industries and countries.

7. Green rapid prototyping and green rapid manufacturing of product, process, and service systems; Eco-friendly digital design and digital manufacturing engineering principles, methods and analytical tools with several simulation and practical industrial / research case studies. Interactive case studies from a variety of industries and countries.

8. Green and cleaner flexible automation, green demand-driven manufacturing and plant design, recipe driven green manufacturing in the pharma industry, disposable, biodegradable manufacturing in the pharma industries, disassembly, demanufacturing and recycling methods and technologies, reuse, and others. Best practice sustainable green manufacturing use-cases based on USA, European, Japanese, Chinese, and other international industrial and R&D examples in a variety of industries. The concept of ecological industrial parks, factories, and industrial facilities designed on the basis of ecologically sound symbiosis models. (This is of great value, since industrial symbiosis yields significant reductions in oil, coal and water consumption, as well as reduces carbon dioxide and sulfur dioxide emissions.) Global reuse of products, systems and sustainable technologies, life cycle thinking and energy efficiency, resource optimization, management & social responsibility, approaches for management and measurement, sustainability drivers and limitations, global market transformation, end-of-life business challenges. Interactive case studies from a variety of industries and countries.

9. Green manufacturing networking and communication / collaboration / video-conferencing processes via the Internet. Smart communities and eco-industrial park networking. Eco-industrial parks are emerging as the primary arena for testing and implementing sustainable green manufacturing within industrial ecology. Similar in some respects to standard industrial parks, eco-industrial parks are designed to allow firms to share infrastructure as a strategy for enhancing sustainable green production and minimizing costs. The distinguishing feature of eco-industrial parks is their use of ecological design to foster collaboration among firms in managing environmental and energy issues. In an eco-industrial park setting, company production patterns, as well as overall park maintenance, work together to follow the principles of natural systems through cycling of resources, working within the constraints of local and global ecosystems, and optimizing energy use. Eco-industrial parks offer firms the opportunity to cooperatively enhance both economic and environmental performance through increased collaboration and networking efficiency, waste minimization, innovation and technology development, access to new markets, strategic planning, and attraction of financing and investment. Interactive case studies from a variety of industries and countries.

10. Internet / intranet-based collaboration and documentation / knowledge management methods, tools and technologies with a sustainable green manufacturing focus. Compliance with international IP and other issues and regulations. Interactive case studies from a variety of industries and countries.

11. International sustainable green manufacturing methods, proceses and R&D case studies focusing on alternative energy resources, applications, and compliant processes. Interactive case studies from a variety of industries and countries.

12. Fuel-cell, windmill / wind turbine and solar panel manufacturing processes with USA, and international examples. Alternative energy sources: hybrid and fuel-cell cars, electric automobiles and power generators. Technologies to transition from a fossil fuel economy to a hydrogen economy. The emission reduction challenge and compliance issues... Oil, gas, coal, and electricity... transportation, agriculture, industrial and residential emission reduction compliance laws, opportunities, methods and technologies. Interactive case studies from a variety of industries and countries. Windmill and solar panel installation and maintenance experiences in New Jersey, in the USA, in Hong Kong and in the Phillippines.

13. China-USA-European-International iSEE:Green focus: Example topics: How do European environmental laws effect design engineering and trade with the USA and Asia? What is the sustainable green design and manufacturing challenge in China? In force as of January 1, 2009, Chinese law states, that governments at all levels should make plans to develop recycling, establish systems to control energy use and pollutant emission, strengthen management on companies with high energy and water consumption, and divert capital into environmentally friendly industries. The recycling law also introduces rewards and penalties for companies, encouraging them to develop recycling by making them responsible for the recycling of their products. What does this mean to green design and manufacturing engineering, and related service industries in Hong Kong, China, and the region? Can China enforce these laws? Will there be a real difference? What are the greening requirements in Japan, India, Russia and Brazil? What are the green design and manufacturing compliance laws and issues countries must follow to be able to trade with Europe and the USA? Interactive case studies from a variety of industries and countries.

14. Global green design and manufacturing supply chain and logistics network: integration methods, tools and technologies of sustainable green manufacturing and other systems. Interactive case studies from a variety of industries and countries.

15. Sustainable green manufacturing project management and communication challenges, methods and solutions: USA, European, Japanese, Chinese, and other industrial and R&D case studies. Cross-functional greening teams, including research, engineering (materials, industrial, electrical, mechanical, environmental, etc.), finance, marketing and sales, human resources, operations, suppliers, customers, maintenance, recyclers, and others . International teams working on a global basis. Project team design and communication skills with team members. Interactive case studies from a variety of industries and countries.

This iSEE:Green series is a simultaneously analytical, as well as practical series of presentations and publications with useful knowledge, that you can turn into 'greening' improvement opportunities in almost any factory, institution, or organization, or system, anywhere in the world. (More details on these methods and tools at: http://www.cimwareukandusa.com)iSEE:Green

A NEW, and Unique Feature Of This SEE:Green Presentation...

International USA / Hong Kong China / Taiwan / European / Japanese Collaboration between university students and professionals.

As part of an informal academic collaborative effort I set up with several universities, we provide links to international Masters students and their work. We also video-conference and real-time interact with professionals around the world. This allows everybody to ask and discuss pressing green challenges... Since we are all in the same boat we can share some of our experiences...

Please feel free to review, comment, and get involved. This is an attempt to increase the global aspects of this presentation for the benefit of all.

Please let me know if you would like to get in touch by email to help a collaborative greening effort. (More details on these methods and tools at: http://www.cimwareukandusa.com)iSEE:Green