Jump To Course Contents and Schedule

This is your latest, therefore the most current schedule.

Last update: December 16, 2006 (Update history: October 25, 2006)

Please Read This! It contains Vital Information about the course as well as all the assignments, homework and grades!

This is a combined Welcome Letter and Course Outline for both the live, as well as the distance learning class. Please read it carefully. Please note, that this document might be updated during the semester. If anything is unclear please contact me.

PLEASE save the TREES! Please DO NOT Print this syllabus. Use this web site to read it in this electronic format; it will be updated during the semester. Thank you!

The On-line/Distance Learning, Live and Hybrid class: Concurrent Engineering

Learn About Concurrent / Simultaneous Engineering, Lean Product Development, Incorporating New Product / Process / Service Innovation & Introduction (NPI&I), and PLM (Product Lifecycle Management) with Digital Design & Digital Manufacturing, Based on a Set of Analytical, Quantitative and Computational Methods, Tools, DVD Virtual Factory Tours, and Case Studies.

by

Paul G. Ranky, PhD

Full Tenured Professor

Registered Chartered Professional Engineer

Member of the American Society for Quality (ASQ), Audit Division and Lean Enterprise / Advanced Manufacturing Division

Also Member of ASEE, IEEE, IEE, FEANI, SAE, PMI

Department of Industrial and Manufacturing Engineering and IT

NJIT, University Heights, NJ 07102 -1982

This is an analytical, as well as practical course. Every subject we discuss is supported by real-world challenges. Then we discuss analytical methods, examples and tools too to help you to solve your real-world challenges. We work in class exactly the same way as progressive thinkers and professionals work in industry... except that we often take it even further. Many of our methods will be truly appreciated by industry in the next 5-10 years, and by then we'll be another 5-10 years ahead of the game... but that is good. We have to be better and be able to continuously improve...

Based on my recent visits to Japan, as Toyota, Denso, Mori-Seiki, Honda, FANUC, Matsushita, Nippon Denso, Panasonic, and other Japanese senior engineers claim and explain:

Excellence in product development is the next core dominent competency in engineering because there is more competitive advantage at the early stage of the design than at any other stage... when combined with concurrent product, process and resource engineering we can half our product development time, or even do better than that... this means, that whilst our competitors achieve one product release, we can offer two, maybe three new product releases... this brings in huge revenues that we can further invest in new product development methods, tools and actual products... Concurrent Engineering with PLM is the big weapon now, that is not fully understood by many...

... and the amazing fact, is that most Japanese companies use American invented and created software to do this... CAD, CAM, PLM, FEA, digital design and simulation tools, computer networking tools, robot control software, interactive multimedia interfaces for machine tools and robots, etc.... does it tell you something? (Oh, yes it does, we need to catch up and learn all these great inventions we create here in the USA too!)

Furthermore, consider this:

With the current level and speed of globalization, hundreds of milions of new, able, educated workers joining the global workforce from China and India and Eastern Europe. We, as they, have only one choice: innovate better, faster and design and produce at a lower cost, than our competitors... this way all able, hard working and ethical workers in our Mother Earth will have a better life. This is fair.

GOOD NEWS! This semester, this course is running in DL mode, but we'll work together during a few optional live laboratory classes, using the most advanced PLM (Product Lifecycle Management) and digital design and manufacturing system in the world: IBM / Dassault Systemes advanced packages. (I have received a close to $3 million USD software donation from Dassault Systemes, Delmia, Catia, IBM !) I will inform you by email and I plan to organize these few live laboratory sessions for the entire class so that you can explore this new technology and supporting methods in detail. I'll be flexible to accomodate your scheduling constraints... no worries. Please stay tuned! THIS WIL BE A VERY EXCITING SEMESTER! Again, these are optional laboratory opportunities.

Here is a very short video of a laboratory demo using our new IBM donated Dassault Systemes Catia / Delmia PLM (Digital Design and Manufacturing Software via Professor Ranky, at NJIT): I formatted this video in QuickTime.mov, as well as for the Video iPod. You can also click the poster frame below to see it running. (It is short but when you come to the optional lab. I'll show you the full system! It is truly amazing... Boeing, Toyota, Airbus, Honda, GM, Ford, Nissan, Renault Formula 1, and many others use it. It is the most powerful PLM system in the world and if Boeing designs aircraft with it, the Dreamliner 787, and Airbus the A380, and Toyota the Camry, then we should have fun with it too!... and we will. Thanks to the donation I have received, we have multiple-seat licences, therefore if you can get to NJIT labs, you'll be able to use it in the GITC engineering labs. Please contact me first. This is a major development curve for us too at NJIT, although I was personally involved in this R&D back in 1985-1987 when I was a Visiting Associate Professor at the University of Michigan, Ann Arbor, MI... a long time ago...)

This is what my recent graduate students wrote about this course:

===========================

'Hi Prof., I did recommend your classes (IE673) and (IE655) to one of my friends at work, who is doing the M.S. in Engineering Management, and he is going to take them both. It has been a great learning experience. One of the things, I have to admit that if it wasn't for you, I would probably never learn how to design a web page, and think it is a complicated process. (thank you). Nirmin'

==============

Professor Ranky:

I would like to express that I admire your way of teaching. I have to admit that I learn a lot of interesting topics and subjects during the Summer of 2005 through "Cuncurrent Engineering" and this Fall through "Total Quality Management", not to mention that I learned how to create the website and post my assignments on it which I had no clue about it before.

The good thing that I can apply use all of what I learned in my work (in small scale) and even in my day life.

So. thank you very much.

Baher Girgis

===========

Thank you again for all of your time and help, it is greatly appreciated. Renee Schleckmann-Bober

=========

Thanks for having you as a teacher and I wish you happy holidays.

Best regards, William Guarin

=========

Thanks! I enjoyed the course… actually learned quite a bit that is very practical to my work at Rolls Royce!

I do find the methods useful... they have helped me to understand a lot of what is going on around here.

Cheers,

Doug

=========

I learned a lot from you. Thanks for the nice reference. Both the bank and the company will be extending offers to me sometime next week.

Thanks & Regards, Ashley

=========

Thank you very much for an excellent semester...I feel that I am walking away with a lot of valuable information that I can utilize.

Regards, Matthew Yencha

=========

Thank you for an interesting course this term. It has given me exposure to a number of tools that I will work to incorporate into the processes my staff and I work through now. With proper planning and review up front, I am confident that I will be able to improve the processes.

Thanks again. David Stibitz

===========

Dear Dr.Ranky,

I had graduated from NJIT with MS in Information systems in May 2003. I had taken the CIS-683 course with you in 2001.... The course which had enabled me to gain a good understanding of Simultaneous / Consurrent engineering, proved extremely valuable in my career as a Business Process consultant. I have been working as a consultant with IBM for over 8 years, worked as a independant consultant for a year, and I am currently in the process of joining Citigroup as a CPI manager.

I am applying for MBA programs at the moment .....

Baiju Krishnan

==============

Professor Ranky,

I am excited to be taking your class again. TQM (Spring 05 was excellent).

David Adwedaa

=============================

Obviously I am delighted to read these emails because they make me work harder and make this course better every semester... THANKS!

========================================================================

Please note, that this document might be updated during the semester. If anything is unclear please contact me. See the contact details below:

Paul G. Ranky, PhD

Full Tenured Professor

Registered Chartered Professional Engineer

Member of the American Society for Quality (ASQ), Audit Division and Lean Enterprise / Advanced Manufacturing Division

Also Member of ASEE, IEEE, IEE, FEANI, SAE, PMI

Department of Industrial and Manufacturing Engineering and IT

NJIT, University Heights, NJ 07102 -1982

Email at NJIT: ranky@njit.edu (Please note, that for reliability reasons I have added another email address: cimware@mac.com . Please use this and send your email again if you don't get an answer from me within 4 working days. I can read the cimware@mac.com account over the Internet anywhere where I have Internet access, therefore even if I am away at a conference on NJIT business we can be in touch.)

Tel at home (in case of an emergency only, 24 hrs, but preferably during normal hours, ( i.e. 8.00 am to 10.00 pm) Tel: (201) 493 9561

Note, that my office is in GITC 2519 at NJIT, Newark Campus

My office hours for the Spring 2007 semester are going to be announced soon. Other office hrs. are available unless I am away on official NJIT business. If these are inconvenient hours for you please ask for an appointment by email cimware@mac.com, and I'll be happy to see you as soon as I can.

Find out more about the Professor’s past and current research work and background at:

http://www.cimwareukandusa.com/aboutpgr.htm

What are Hybrid Courses?

Please note, that this course typically runs in DL, live and/or hybrid formats at NJIT.

hy·brid - noun - something of mixed origin or composition; something, such as a computer or automobile plant, having two kinds of components that produce the same or similar results.

Hybrid courses at NJIT, also known as blended or mixed mode courses, are courses in which a significant portion of the learning activities have been moved online and time traditionally spent in the classroom is reduced but not eliminated.

The goal of hybrid courses is to pair the best features of face-to-face teaching with the best options of online learning to promote active and independent learning and reduce class seat time.

Using instructional technologies, the hybrid model forces the redesign of some lecture or lab content into new online learning activities, such as case studies, tutorials, self-testing exercises, simulations, and online group collaborations.

This site (ref.: http://media.njit.edu/hybrid/) was created in support of NJIT's Pilot Program in Hybrid Learning and the Weekend University.

"Within five years, you'll see a very significant number of classes that are available in a hybrid fashion," says John R. Bourne, a professor of electrical and computer engineering at Franklin W. Olin College of Engineering who is editor of the Journal of Asynchronous Learning Networks. "I would guess that somewhere in the 80- to 90-percent range of classes could sometime become hybrid."

And he says he expects to see more students choose to take online courses even if they live on campus.

"Hybrid Teaching Seeks to End the Divide Between Traditional and Online Instruction" by Jeffrey R. Young, March 22, 2002, Chronicle of Higher Education

Ref.: http://media.njit.edu/hybrid/

General Notes As an NJIT undergraduate, graduate, live and/ or Distance learning, or in other words eLearning Student, or hybrid course student you are entitled to benefit of significant FREE computing resources, meaning hardware, software, as well as on-line email, web-site storage space, and related Internet and NJIT intranet server services. The steps below intend to help you on how to set up a web page for documenting your assignments for this course. Please read and follow each step. Obviously if you already have a web page, either through work, or business, or otherwise, please feel free to use that, or the one you prefer. (All we want is for you to learn the method, and then put all your assignments on the web, learn how to manage your knowledge over the web, and then email your URL with your assignments to the instructor for grading). Note, that you can use any suitable web authoring software. NJIT has a few on free offer too. These are the steps to follow (as provided by NJIT's IT and Computing Services): Hopefully all works... I'd like to see your beautiful webpages! These are the steps my students suggested in the past to follow when uploading web pages to the NJIT server (Note: I use professional servers; I do not use the NJIT server, therefore if you need help please contact the NJIT computing help desk, and/or network with other students via chat groups). Read these instructions (kindly offered by Ashley John). Last, but not least: ALWAYS test your uploaded assignment using your own, as well as somebody else's computer, to make sure, that everything works fine. (If you don't have a second, independent computer on the web, ask one of your classmates, or friends to check it for you, by sending him/her an email with a full URL in it. The 'full URL' should have this, or similar format: http://www.mycoursewebpage.edu). Also note, that besides the class discussions (in our live class), the eLearning pack 3D eBook CDs / DVDs have several examples on the architecture of simple and complex web-pages. All of these are in open source, please study them! Of course open source does NOT mean that you can put an entire eBook, or DVD video, etc. onto the web, NOT even on your own server! This action would be illegal, since you would break the USA and the International Copyright Laws! Don't get in trouble with publishers... it is nasty and costly, and if you illegally put any published and copyrighted material on teh web, you'll definitely loose in court... PLEASE OBBEY THE USA and the International COPYRIGHT LAWS! DO NOT ILLEGALLY COPY ANY OF MY, or somebody elses PUBLICATIONS! What you can do of course is use individual objects, images, video xclips in your assignments, also spreadsheet templates customized with your own data, etc. with credit (i.e. include the sourse in the Bibliography). This is legal. The 21st Century Engineer must be a professional information searcher, information and knowledge creator, as well as somebody who can reason over several different sets of information and then select the best possible solution path under constraints... not an easy task. In order to help this process, in this course we'll visit NJIT's wast and advanced electronic library, see some of the typical information searches and how the results can be evaluated. For our purposes, we'll use NJIT's SCOPUS electronic database. You can reach it via: http://www.scopus.com.libdb.njit.edu:8888/scopus/home.url, all you need is your UCID and password (as offered by NJIT to every NJIT student) to access this site. As always, Happy Learning, Professor Paul G Ranky, PhD

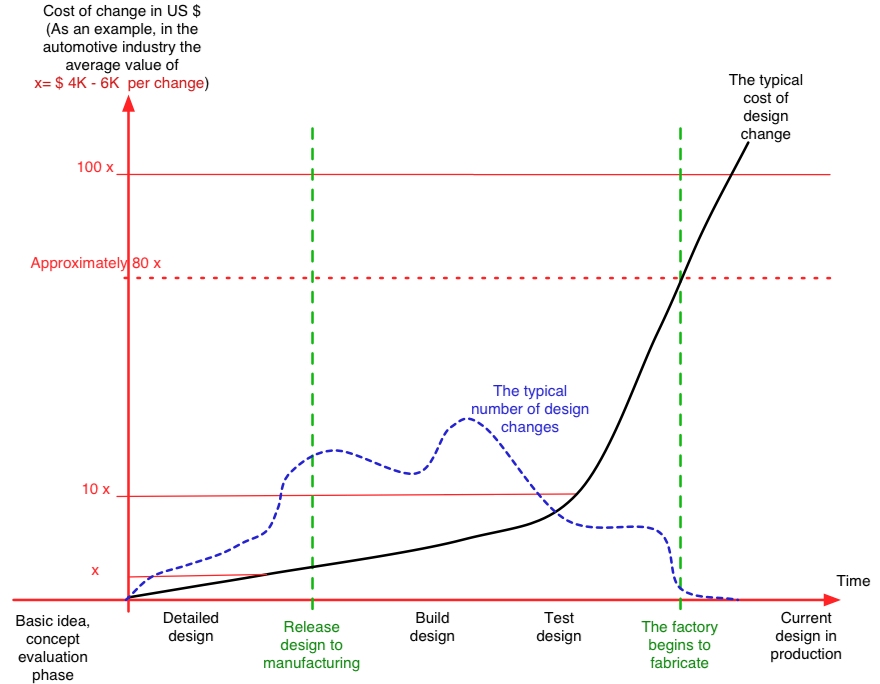

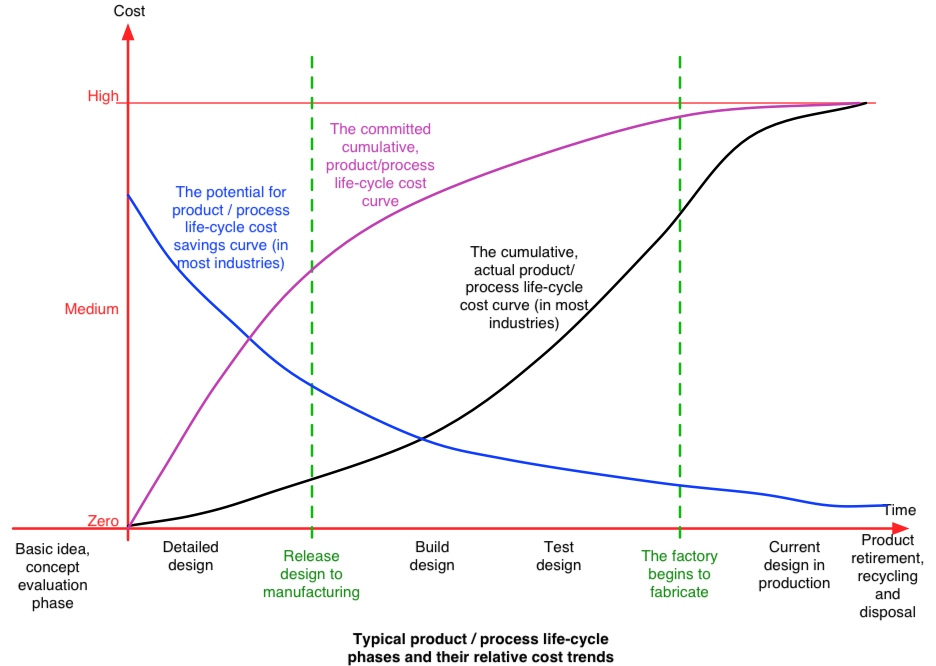

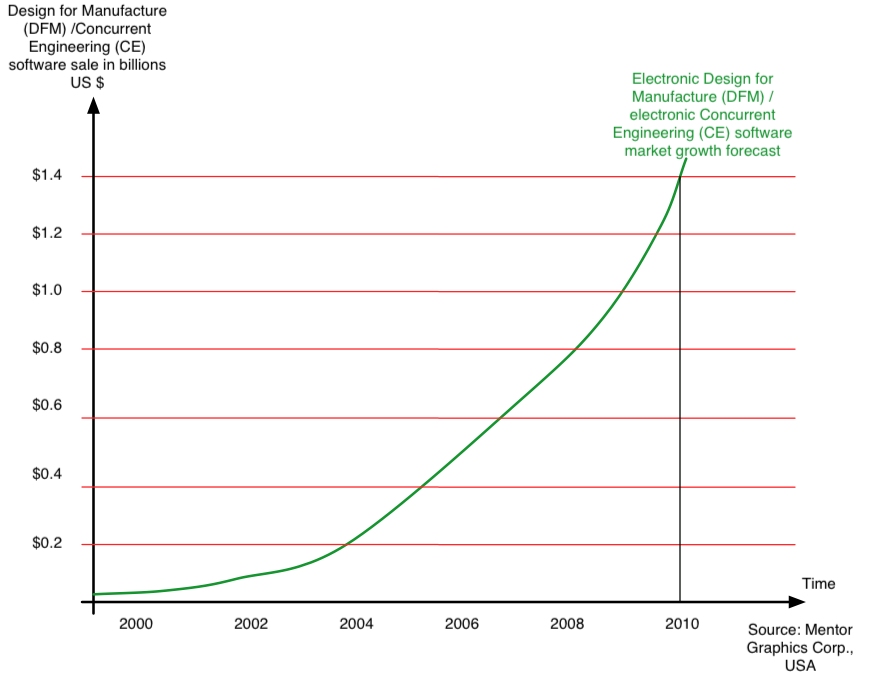

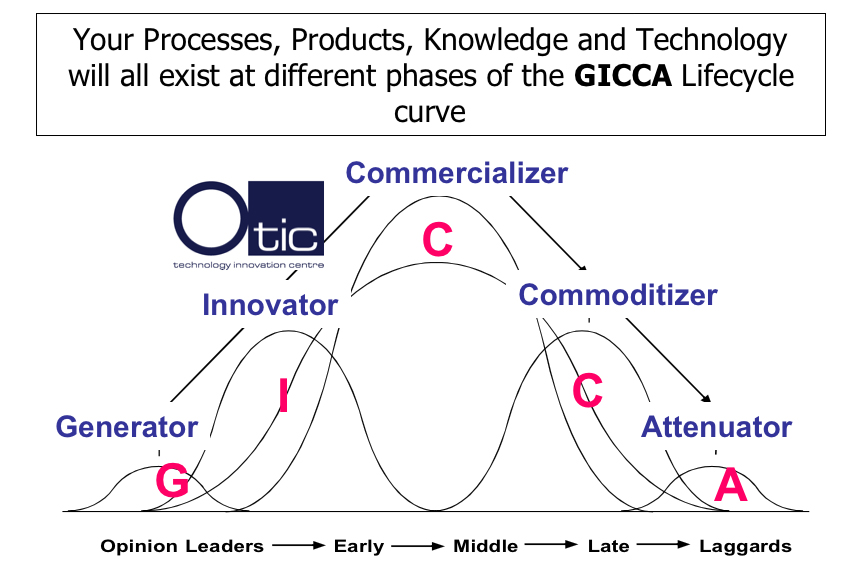

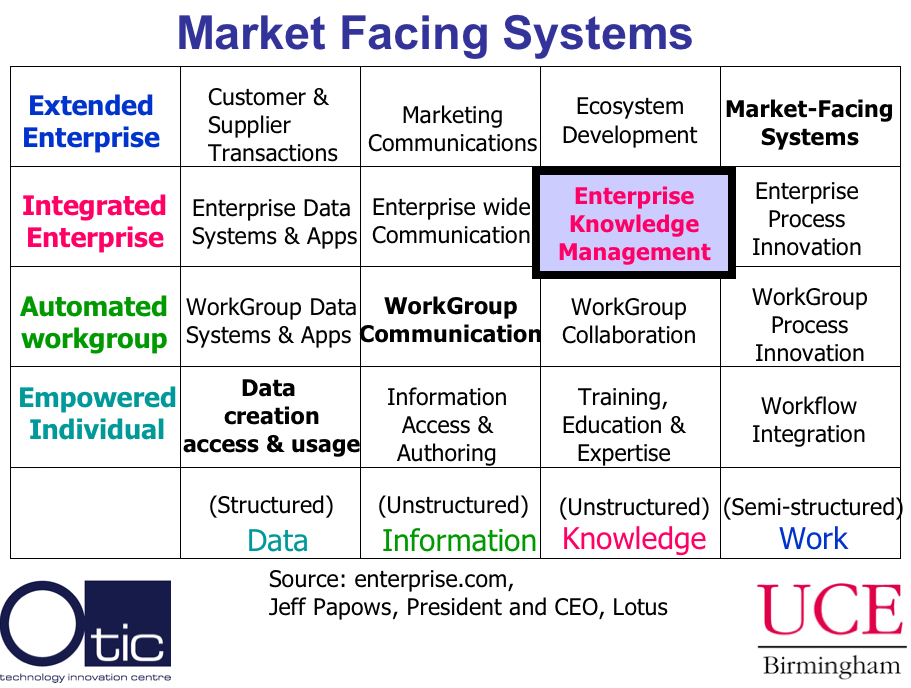

Contents (IE655) Course All Options: Live, Hybrid and Distance Learning (DL, or eLearning, the same). NJIT IE 655 Welcome to IE655: one of the most useful engineering / engineering management courses you’ll ever take! Please read these notes and work hard on your assignments. What you'll learn in this class will help you to be amongst those who will continously win and prosper. If anything is unclear please call me or email me. I am here to help you! In IE655 we discuss and learn a conceptual, as well as a practical approach how to innovate, and minimize the time required to successfully execute complex product / process / resource design focused projects. Techniques utilized and discussed in detail include systems analysis and integration, needs analysis, product modeling, system modeling, process risk analysis, Taguchi design of experiments methods, Weibull reliability analysis methods, collaboration and integration methods, rapid prototyping, digital design & digital manufacturing, design for manufacturing / assembly, and others. Relevant open source software is employed and made available to students in the form of a customized eLearning Pack, and commercial software for educational purposes via the NJIT servers. The course should be of interest to individuals concerned with integrated product/ process innovation and introduction to the market, minimizing lead time, reducing project development cost and time to market new products, and/or services. Narrative Description of the Course The purpose of concurrent / simultaneous engineering methods is to cut product and/or service process development lead time, to reduce waste, to reduce the number of costly product design changes, to improve quality, and to create a lean workflow. This is applied from concept to integrated product/process design, manufacture, assembly, maintenance and after-sales support, based on analytically established customer requirements, and process models. The diagram below clearly illustrates the essence of this course. As it can be seen, it is every company's aim to innovate, create new products, processes and services that are required by customers, that are high quality, and can be introduced to the market at a competitive price. The diagram below clearly illustrates the extremely high cost of product design changes. This is typical without deploying concurrent engineering / PLM methods... in the IE655 class we'll learn methods, tools and technologies, that will lead us to innovate, and minimize the number, and therefore the cost of changes during the entire lifecycle of a product (hence the terminology: PLM). . Furthermore, as illustrated below, it is important to understand, that Concurrent Engineering, combined with PLM, Total Quality Management, and Project Management offers major product life-cycle cost reductions. As you study the graph below, consider the following: In engineering systems the term 'life-cycle cost' means the sum of all the costs, both recurring as well as non-recurring, related to product, structure, system, process, IT, and/or service during its life span. (A typical life-cycle is illustrated below.) As you can see from this graph, life-cycles typically start by identifying a customer need, a requirement, a want, a desire, and/or a sound business opportunity, and end with product/process retirement, conversion, re-engineering, recycling and eventual disposal activities. (Note, that in the case of a modern, environmentally friendly concurrently engineered product/process design system, 85-90% of products are eventually re-used and recycled. Since by understanding the underlying drivers and processes of concurrent engineering, the opportunities for saving valuable product/process design and development cost and time are huge, the aim is obviously close to 100% re-use and re-cycling, and as we will discuss this issue in the course, there are already good examples for achieving this goal... Besides others, the graph below underlines the fact, that concurrent engineering economic studies, process-by-process cost and gain assessments are essential part of the big picture, because they help to analyse and compare alternatives in virtual environments, costing a lot less than real-world experimentation on the shop floor when the product/process is already in full swing production and the commited costs are already high. We can furthermore see, that the greatest savings occur at the acquisition phase, in other words around the basic idea to detailed design transition phase. This is why a factory with a future (i.e. a digital, networked factory) will have to understand and master concurrent engineering, PLM and NPI&I methods and apply them at all stages of the business to be able to successfully compete. It is also important to recognize, that as shown below, the commited cummulative life-cycle cost curve increases rapidly during the basic product/process idea to detailed design transition phase. In general typically 80% of life-cycle costs are 'locked in' at the end of this phase and at the beginning of the 'release design to manufacturing' phase by the decisions made during the requirements analysis, preliminary and detailed design phases. As illustrated by the cummulative, actual life-cycle cost curve, only about 20% of actual costs occur during the acquisition phase, in other words around the basic idea to detailed design transition phase, with about 80% being occured at the product construction, operation phase. The conclusion is, as shown below, that the concurrently engineered NPI&I activity must understand the potential for product / process life-cycle savings in all processes, with their requirements and risks involved. This should include their time and cost demands too. The key then is to simulate these issues in advanced virtual (digital) environments, and take decisions as early as possible (i.e. 'front loading') to avoid dead-end paths and costly changes downstream... easier said than done! (Note, that this statement is true for every product/process, IT, and service product development activity!) . . It is interesting to see, that the above illustrated principles apply to literally every industry, but most importantly to all manufacturing and design industries, as well as to IT and service environments. As an example, in the IT industry the opportunities for savings are enormous, due to the fact that over 85% of IT projects fail (1990-2004 figures). This is costing the USA economy over 56 billion (!) USA dollars. Using concurrent engineering and NPI&I methods this amazing level of failure can be reduced significantly (as a reference only 10-15% of engineering projects fail, and when they fail mostly they overrun, rather than truly fail, like don't work... or crash like software does...). The major challenge though is to convince IT professionals to actually learn, understand and then apply these methods during their everyday work, versus jump into code-writing, clicking... as many of them do even now as you read this text... and they are charging for every click with the mouse... big $$$$... Of course, the root cause is to convince many (not all) computing and information sciences professors to change the way they teach IT, information sciences, software design and computer programming... but this is outside the scope of this class... Nevertheless any fool can see that even if we could just save 10% of the $ 56 billion, we could gain $ 5.6 billion every year; not an ignorable sum... the potential savings of course are at least 80% of the 85% failure, therefore we really talk about saving 80% of $ 56 billion = $ 44.8 billion USA Dollars in the USA only... World-wide this figure is estimated to be several times this value... imagine how many hungry kids we could feed out of this money... and how many could get university level education... now you feel the pressure; amazing but all true! To move on with some positive thoughts, as seen below, the good news is that the above discussed challenges are recognized by many. The Design for Manufacturing (DFM) / Concurrent Engineering (CE) / PLM software market is forecast to grow very agressively not only in the mechanical (like the automotive) but also in the electrical, and electro-mechanical industries. This is because the electronics industry recognizes the significant cost saving, quality improvement, and time-to-market reduction opportunities with CE. As an example, at a recent Design for Manufacturability conference in San Diego, CA, USA, the electronic engineering community expressed their views, that 'DFM / CE / PLM solutions have emerged to help designers to cope with process variability reductions and yield increase' (... hope you recognize the link here with what we teach in Total Quality Management, IE673). As EE Times, the industry newspaper for electronic engineers and technical management (by United Business Media, USA) reports in their June 14, 2004 issue, 'taking one of the boldest steps yet to merge design with manufaturing, Magma Design Automation Inc., USA announced an integrated solution...' Furthermore, IBM and academic research partners are working on methodologies for manufacturing-driven design rule exploration, physical verification, design rule checking (DRC), and other hot CE topics... As Vasilios Gerousis, Chief Scientist at Infineon Technologies AG put it: 'Design and process parameters need to be adjusted at the same time'; a clear success for concurrent / simultaneous engineering principles! The graph below illustrates the above planned, industry-driven, drastic electronic design DFM/CE software growth rate. . In order to lead the above outlined plan, our students are prepared for this challenge and are educated to respond to the rapidly growing employment opportunities in the field of concurrent / integrated product / process, PLM and service system design engineering management. In the IE655 course they learn several well established methods in-depth, such as quality function deployment, requirements analysis, collaborative concurrent engineering (and service) process modeling, process failure mode and risk analysis methods, Poke-Yoke, Kanzei, rapid prototyping methods, PLM (Product Lifecycle Management), NPI & I (New Product Innovation and Introduction), and others, including methods, tools and technologies in the product / process / service system design field, covering the following: The course is supported by a comprehensive eLearning package (this pack is the same for live, hybrid and distance learning students) with some printed material, and several web-browser readable, open source 3D interactive multimedia eBook CD-ROMs and DVDs and DVD videos. It includes real-world research and industrial case studies, as well as open source, professional active code and spreadsheets, that the students can customize when developing their assignments with their own data. To summarize, the methods taught in this course are relevant not just to innovative design, manufacture, test and quality control of products, but to a large variety of services too, because they reduce development costs, and improve working capital management, by offering powerful methods and software tools. Upon completing this program of study the candidates will be able to understand Concurrent/ Simultaneous Engineering, and related PLM, Digital Design & Manufacturing, NPI&I, and total quality engineering management methods and tools. Note, that besides the above, in this semester we'll specifically focus on PLM / Digital Design & Manufacturing. Why is the course needed? Concurrent Engineering represents a structured, logical framework which supports a systematic approach to the integrated, concurrent design of products and their related processes, including manufacture and support. This method is intended to ensure that developers consider all elements of the product life cycle from conception through to final disposal, and re-engineering / recycling, including quality, cost schedule and user requirements. In contrast to the old, conventional, or sequential product design method, Concurrent Engineering focuses on customer satisfaction, on teamwork as well as on Design for Manufacturing, Design for Assembly, Quality and Total Lifecycle issues. We further illustrate this concept with Dr. Peter Rayson's GICCA enterprise lifecycle curve (Technology Innovation Centre, University of Central England, Birmingham, UK). As it can be seen from the figure above, and below, it is essential to understand that none of the Concurrent Engineering or CIM (Computer Integrated Manufacturing) methods work in practice unless they are applied to all levels of the enterprise, that they are introduced gradually and that they are managed by people who understand and support them. (In order to promote this thought CIM, or Computer Integrated Manufacturing is now often referred to as the lean, or agile, or adaptive, digital manufacturing and design system, preferably implemented in a digital factory (more on this topic in a web-article...). It is furthermore obvious from the table below, that the extended enterprise (with a future) must focus on all aspects of product / process and service system innovation and introduction to the international marketplace. This process needs knowledgeable and empowered individuals who understand the importance of enterprise knowledge management, digital design & digital manufacturing, exactly the professionals industry needs, and this course aims to develop! Note, that various views and angles of this complex topic is addressed by Ranky in this Concurrent / Simultaneous Engineering course, in his Total Quality Management class, and also in his Project Management and Lean, Flexible Automation / Manufacturing Systems Engineering classes. . In broader terms, the aims of CE, PLM, or integrated lean, or agile, or adaptive, 3D digital design and manufacturing are very clear: getting rid of waste, reducing the number of costly changes, integrating product and process engineering better, focusing on high quality at low cost, offering product data management and PLM within all the companies involved in the product creation and manufacturing processes, organizing our knowledge in our minds, and helping us to focus on new innovative opportunities driven by the customer. The key is to be able to integrate the In other words, CIM (Computer Integrated Manufacturing), Total Quality Management, Engineering Project Management and Concurrent Engineering, and PLM (Product Lifecycle Management) address the whole enterprise, including products, processes, controls and resources, enabled and created by humans, machines and networked global partners, including the business systems, product design, process planning, manufacturing planning, the shop floor, packaging and maintenance via the internal, as well as the external supply chains. As we can see when we analyze successful companies, innovative, quality design is very important: As an example look at Toyota, BMW, DENSO, Nissan, Honda, Boeing, Airbus, Dassault Systemes, or another giant industry innovator: Apple Computers. Engineering excellence is central to Apple’s vision: Apple’s leader, Steve Jobs, in Paris at the Apple Expo 2005 talked about the beating heart at the centre of Apple’s core, the company’s world-class engineering teams. The October 24th Time Magazine issue features Steve Jobs on the Cover holding a Video iPod and an iMac with the words "What's Next". (The article is available to subscribers, but is also available in full at TimeCanada).

The product now is the iTunes Music Store and iTunes and the iPod and the software that goes on the iPod. A lot of companies don't really have control, or they can't really work in a collaborative way to truly make a system. We're really about a system. Jobs also provides more insight into his opinion about the new video capabilities of the iPod: "There is no market today for portable video," he says. "We're going to sell millions of these to people who want to play their music, and video is going to come along for the ride. Anyone who wants to put out video content will put it out for this. And we'll find out what happens." ... and some more facts about Apple (to underline the fact, that concurrent engineering principles, as the CEO has identified the key, works well), as Apple is heading to become a $20 billion corporation: - Net Mac sales increased 27% year over year ==================================== Ranky: Well, this is what happened: within 2 weeks of the introduction of the first Video iPod, Apple sold 1 million videos for it over the iTunes music store, and within 1 year the music iPod gained 60% market share in Japan... where Sony and others typically rule... Apple's market share of the same product in the USA is over 85% for downloads, and 75% for hardware devices... real success, and real concurrent engineering methods... and you can learn many of these in this class. I firmly believe, that the key to all this is the following: 1. A good, successful design is based on culture, created by progressive thinkers (i.e. HUMANS!), and the 2. Methods and toolset MUST have a strong emphasis on integration, like Concurrent Engineering, TQM and PLM. Isolated thinkers, with isolated tools will NOT succeed in our complex, networked, global infrastructure of creators, producers, manufacturers, and consumers. Sounds really simple, nothing really new, nevertheless not easy to actually deliver... but we'll learn this in this class. ===================================== In a different industry, we can identify similar eager to develop new products, processes, resources and service. As BMW's Dr. Burkhard Goeschel (CTO) states: The BMW Group is the only major manufacturer of automobiles and motorcycles worldwide that concentrates entirely on premium products and outstanding quality for all its brands and across all relevant segments. Like all other members of the automotive industry, the BMW Group operates in an area characterized by two contradictory developments. On the one hand, customer demands as well as requirements within the society, are constantly on the rise. On the other hand, competition within the industry is continuously shortening development times for new models even as cars become ever more complex products. Therefore, developing and implementing innovations is the key element in the BMW Group's strategy to meet this twofold challenge and to maintain its position at the forefront of the automobile industry. Innovative products are clearly distinguishable from the competition, create desire and thus command a higher prize - with all three points being of vital importance in the premium segment. The company acknowledges only products and components that are clearly recognized as useful by our customers. In the same way, research activities are focused on so-called strategic innovation areas such as powertrain or driving dynamics in which the company seeks to maintain or achieve technological leadership. Two areas that enjoy top R&D priority are Sustainable Mobility and Intelligent Mobility: Sustainable Mobility The fuel of the future however, will be hydrogen. If generated with the use of regenerative energy sources, hydrogen is the only truly emission-free energy-carrier available. With the initiative BMW CleanEnergy the BMW Group strives to establish the hydrogen-powered internal combustion engine as the propulsion system of the future. Far from being a new player in this field BMW Group has started researching hydrogen technology 25 years ago. In 2004 the H2R prototype-vehicle set nine world records for hydrogen-powered cars, including a top speed of more than 300 km/h, thereby clearly showing the future potential of the hydrogen-powered internal combustion engine. Intelligent Mobility (Note, that whilst GM, Ford and Chrysler shrunk between 45 to 17%, BMW actually grew 17% in 2005-2006... guess why...) ========================== A few words about Lean Product Development... by Nancy Rouse-Talley. (She is a freelance writer who focuses on technology subjects, Desktop Engineering, December 2006) '...Successful execution of a lean manufacturing program requires assessing processes, recognizing bottlenecks, and making improvements that not only eliminate holdups but improve efficiency. Simply automating existing processes is not the best way to implement product lifecycle management (PLM) programs. In fact, it might be a recipe for disaster because computerization could simply speed up unproductive processes without improving them, leading to an endless cycle of ineffective changes. Software that manages design data, moves it to the factory, and promotes factory automation should be used once processes are streamlined and improved. Programs such as UGS Corporation’s Teamcenter, PTC’s Windchill, Agile Software Corporation’s PLM products, Centric Software’s Product Intelligence Software, and Dassault Systèmes’ Enovia Virtual Product Lifecycle Management (VPLM), Smarteam, and MatrixOne make it easier to share complex engineering data across the enterprise. Digital manufacturing programs such as UGS’ Tecnomatix and Dassault’s Delmia, on the other hand, help manufacturing engineers validate production processes. Companies that in the past were primarily concerned with lean manufacturing now also focus on lean product development. Lean methods have formed the foundation of Japanese automobile manufacturer Toyota’s factory processes for more than 50 years, for example, but today the company also uses PLM to perpetuate lean product development processes.'... ========================== For Whom is the Course Designed? Graduate / Master of Science programs in IE (Industrial Engineering), in EM (Engineering Management), in MnE (Manufacturing Systems Engineering) as well as an elective course for Graduate Mechanical Engineering, Graduate Computing Science and Graduate Environmental Engineering, and Biomedical Engineering students. Note, that students with science background can take this course too. We follow a modular approach that makes the topic very adaptable to a variety of different environments. This approach has been successfully tested and run for several years at NJIT as well as on a consulting basis at large companies and software houses, such as Rolls-Royce, IBM, GM, Ford, Raytheon, and others. Furthermore, the course is aimed at graduate research students, professional engineers and managers working in industry, wishing to learn about new, integrated design and manufacturing methods, tools and technologies, and management methods, for the purpose of improving products and services, and to learn how to innovate in a cost effective and productive way. Note, that if you have taken the IE673, Total Quality Management course with me, you will find this course to be an integrated part of our advanced project management, total quality and new product/process/service creation approach. Live as well as Distance and Hybrid (blended) Learning (eLearning) Students purchase their educationally priced, customized eLearning Packs from the NJIT Bookstore (PLEASE ask for the Spring 2006 IE655 eLearning Pack. The pack changes every semester, therefore you need the current version. Both Live, as well as eLearning (DL) students get the same type of eLearning Pack from the bookstore). Every eLearning Pack is different, because it is customized, and this semester includes the following incredible resources: Important notes: Reading for a degree... A few words about 'reading for a degree'... for hundreds of years, academics all over the world emphasized the importance of reading for a degree. Since we fully support this philosophy, in the eLearning Packs you'll find significantly more material than required for an 'A', to help even the most progressive students to learn more. Also, you are encouraged to use the Internet, and the NJIT Library. Here is a short list of excellent resources that will help you to deepen your understanding of the subject area of this course: Academic Calendar Please look up the accurate dates on the NJIT website. This is a short summary: Sunday Schedule: This semester is the equivalent of 15 weeks of study. You have to complete and submit 6 assignments (see them below in detail). There is no final examination, the course is assessed based on 6 assignments. The schedule and deadlines for all assignments are below. All assignments should be in electronic format. If there is something not clear, please email, or call, or make an appointment and see me (as specified above). There is a limited number of rework options (typically one per assignment) to assure that you do your best and learn the most, and of course get the fair grade for your efforts. I am keen to help, but I need your help to be able to help you. Your hard work is the best help for all of us to acieve this goal! If you win, we all win! Class 1 Introduction and overview of the course as well as the subject: Concurrent / Simultaneous Engineering (meaning exactly the same) and PLM, in a traditional and in a modern design and manufacturing enterprise. Object oriented (OO) and globally distributed enterprise models. Systems and integrated processes are explained. Our discussions are supported by DVD videos and virtual factory tours, and have an engineering management focus on how to find and reduce product design and process design related waste; on how to support integrated product / process design concepts and models, how to win over your competitors by following digital design & manufacturing principles and technologies, and how to innovate. Innovation is key in our 'Innovation Economy', in particular in the USA, competing with low labor cost nations on a global basis. If you learn about CE / PLM / Digital Design & Manufacturing, you basically learn how to secure your own job for a very long time! Student Activities (this is what you should do to get an 'A' in this class, and most importantly learn the subject): Class 2 Concurrent Engineering and PLM Methods, Tools and Technologies. The Product Development process. Focus on integrating design and manufacturing processes for the purpose of cutting waste, and improving quality. PLM methods and tools for frontloading the product development process. Submit by the End of This Week! (note, that 'End of Week', for all cases means Friday, 5.00 p.m. of that week)! Assignment No. 0: Design your Own Concurrent Engineering, Digital Design and Digital Manufacturing System Design Challenge with the 4 Collaborative Companies in your eLearning Pack (1 page Executive Summary). This is a short electronic presentation by each student entitled: 'My PLM / Digital Design & Manufacturing challenge, my collaborative companies, and my plans for collaborating with them in order to develop, innovate and bring to market my new product/process design'. Please address briefly all these issues. You can change the focus later as you develop the project, but you'll need my approval to go ahead. This is why I need the single page executive summary emailed to me. (This is also a good time to start to set up your web page...) Also, include your project Title, Author (Name, your photo, your class, date, your eLearning Pack serial number and the collaborative companies you have (a MUST!). I will respond to this by email, comment and hopefully accept your plans. When you have your web page up and running, include this Assignment 0 to have a nice, integrated documentation approach to all of your assignments on the web. Don't miss the fact, that this is a Concurrent Engineering, PLM and NPI&I - focused class! Make sure, that your assignments reflect this! Also, you must collaborate with teh 4 companies in your eLearning Pack! Classes 3, and 4 Concurrent Engineering, PLM and NPI&I (New Product Innovation & Introduction) in our rapidly growing research and development world = DVD Video Lectures and full screen, high quality case study videos. Enjoy; you are seeing and experiencing the past and the future... Submit by the End of This Week! Project/ Assignment No.1: Concurrent Engineering Video Lectures (20%) (Relevant eLearning Pack Resource: work through the DVD videos). Take notes as you watch them. You'll need these notes in some of the other assignments too! Typical Mistakes: Why am I loosing grade points in this assignment? QFD (Quality Function Deployment); Component-oriented Requirements Analysis is discussed with 3D Virtual Reality examples as an OO Concurrent Engineering / PLM methodology. Note, that we are dealing with the "Product Planning Stage QFD diagram/ matrix. i.e. the very first one. Student Activities: QFD (Quality Function Deployment) / Requirements analysis is discussed with 3D Virtual Reality examples as a Concurrent Engineering methodology. Focus on the Assignment this week! We like professional quality assignments! Submit by the End of This Week! Assignment No. 2: QFD1 / CORA (Quality Function Deployment; Component Oriented Requirements / Needs Analysis). In terms of assignment development method, please follow the CORA CD-ROM in your Learning Pack. (Relevant eLearning Pack Resource: Requirements analysis CD-ROM inside the CE book, as described above) When developing the QFD1 matrix for a product try to put down all customer requirements for the WHAT’s side, prioritize them, then create the HOW’s, this is the "engineers’ voice", then the HOW MUCH’s, which will give you the parameter ranges for satisfactory data and then develop the rest of the correlation and the comparative quality models on the right hand side of the matrix. The crucial thing is that in the report you should explain what you have done and why? Please note, that the best assignments show evidence that the student has worked through the learning material provided in the 3D eBook. Therefore feel free to incorporate digital images, text and even video clips or 3D VR objects provided into your assignment; nevertheless never forget to credit the source of such objects in the bibliography. Typical Mistakes: Why am I loosing grade points in this assignment? FMEA: The Failure Mode and Effect Analysis, or Process Failure Risk Analysis methodology and its use in CE. Interactive FMEA modeling / Disassembly Failure Risk Analysis modeling with the 3D Virtual Reality examples on the DFRA CD-ROM. Relevant eLearning Pack Resource: Study the DFRA CD Case Study! Note, that the DFRA CD-ROM is focusing on using the FMEA method for disassembly process failure risk analysis. This CD educates a the method and offers examples and solutions, as well as active code-tools for you to execute (in the form of MS Excel templates). Learn this method, as well as read the book chapter on FMEA, and then based on the MS-Excel Template in the DFRA CD develop process/ design (potential) failure modes of YOUR product, that you are designing. Please make up missing data. Design For Manufacturing, Quality, Assembly, KANRI, KAISEN, MUDA, MURA, MURI, POKA-YOKE, the role of Quality Circles, and other methods discussed with 3D Virtual Reality examples. (Part 1). Submit by the End of This Week! Assignment No. 3: Process Failure Mode and Effects / Failure Risk Analysis in the CE Context The student’s main task is to pay attention to the multimedia presentations, to take notes on every important issue, item, principle, and example, to interact with the tutor (on Email, Fax, Telephone, etc.) and the class members (on Email, Fax, Telephone, etc.) and fully understand the topics covered. Student Activities and relevant eLearning Pack Resources Please keep this in mind: We are interested in seeing that you understand the methods... we don't want you to spend your entire life on these assignments... you follow...Please note, that the best assignments show evidence that the student has worked through the learning material provided on CD-ROMs and in the book. Therefore feel free to incorporate digital images, text and even video clips or 3D VR objects provided on the CDs into your assignments; nevertheless never forget to credit the source of such objects in the bibliography. Project/ Assignment No. 3: Process Failure Mode and Effects / Failure Risk Analysis in the CE Context (20%) Typical Mistakes: Why am I loosing grade points in this assignment? Design For Manufacturing, Quality, Assembly, KANRI, KAISEN, MUDA, MURA, MURI, POKA-YOKE, the role of Quality Circles, and other methods discussed with 3D Virtual Reality examples and classroom exercises. Rapid prototyping methods and solutions (Part 2). Based on the Rapid Prototyping CD-ROM (inside the textbook, in the DVD): Focus on the engineering related challenges/ questions in this CD. Try to answer 10 selected questions of your choice! Incorporate these answers into the Assignment below! Design for Demanufacturing, disassembly, Virtual Product Disassembly over the web, and other methods discussed with 3D Virtual Reality examples and classroom exercises. Rapid prototyping methods and solutions. Networked Concurrent Engineering systems in digital collaborative factories. Discussion on network modeling methods and tools. PLM (Product Lifecycle Management), NPI & I (New Product Innovation and Introduction). Student Activities: Submit by the End of This Week! Assignment No. 4: Rapid Prototyping Study (20%) The students' main task is to pay attention to the multimedia presentations, to take notes on every important issue, item, principle, and example, to interact with the tutor (on Email, Fax, Telephone, etc.) and the class members (on Email, Fax, Telephone, etc.) and fully understand the topics covered. Typical Mistakes: Why am I loosing grade points in this assignment? Class 12 and 13 (Don't worry, it's almost over...) Concurrent Engineering / PLM Team management methods and issues. The TOPS method (The Ford Motor Company). Virtual teaming methods over the Internet. A 3D Virtual Reality web-based method and code is discussed in detail. Student Activities: Class 14 and 15 (Note, that Classes 14 and 15 are kept for Assignment related project improvements) Submit This Week! Assignment No. 5: Concurrent Engineering Product Design Assessment and Improvements: New Product Innovation & Introduction (NPI & I) Challenges Part 1: Innovative Toy PLM Design (20% max.) and Part 2: PLM / Digital Design & Digital Manufacturing Transition Plan, Marketing Plan (Press Release of your new product/ process/ service) (20% max.) Documentation Structure for Assignment #5 11.55 pm, Saturday, May 5, 2007: ABSOLUTELY THE LAST DAY TO SUBMIT any new assignments, or reworked assignments! All submissions MUST be electronic. Please email me the final URL of your course assignment webpage, with the last versions of all assignments in it. Schedule and due dates: As above. The total course duration is the equivalent of 15 weeks of study. Students will be required to complete each assignment. Assignments totaling 120% max. Grade "A" for this class requires min. 92% total. Feedback to the Anonymous Total Quality Feedback Form: IE655 (January 21, 2003) 1. JIT (just-in-time) manufacturing: note, that we'll deal with this briefly, nevertheless the IE673 TQM course deals with this in detail; 2. Information management in product/ process integration (we are going to deal with this in detail, see above). 3. The lean manufacturing approach: note, that this is similar to (1) above, nevertheless we'll deal with this briefly. 4. Using simulation tools/ products to determine product effectiveness; we are going to deal with this in detail, nevertheless due to the depth of the simulation opportunities we won't be able to exhaust the topic in this course. It is over! Congratulations! You can now analyze and improve many products and services! PLEASE save the TREES! Please DO NOT Print this syllabus. Use this web site to read it in this electronic format; it will be updated during the semester. Thank you!

An object - oriented (i.e. modular product, process, service design) approach to the introduction of various product and process design methods, tools, technologies and their management issues within a variety of small, medium and large enterprises for the purpose of reducing lead time, and cutting waste.

There are many methods and solutions to innovate and develop new products and processes, to cut down waste and to improve an organization, a design office, a manufacturing enterprise, or a product. One major discipline is Concurrent Engineering (CE). CE is also widely known as Simultaneous, or Parallel Engineering, and lately referred to as PLM (Product Lifecycle Management) reflecting the fact that in our knowledge age we are dealing with digital factories networked all around the world.... exciting, but also challenging...

“At its core Apple has great engineering and confidence that it has the ability to take complex technology and make it easy for the end user.” Remaining relevant in a changing world is critical. The idea of making powerful technologies easy to use matters: “That need is becoming more necessasry as technology becomes more complex”, he said.

“Apple does that better than any other company in the world. What makes us different? Most of our competitors don’t have engineers anymore. Everyone else designs in the Far East.”

Given that claim, a question was asked as to why Apple says “designed in California”, rather than “designed in the US” on its products. Jobs responded: “(It’s) because we like California. It is where we are from. It’s not because we are ashamed by the US”.

In it, Jobs talks about how and why Apple continues to be innovative in this industry. He points to their product development cycle as "deep collaboration" or "concurrent engineering". Products don't pass from team to team. Instead products are developed in parallel by all departments "in endless rounds of interdisciplinary design reviews".

Jobs also places emphasis on control. Through controlling the hardware and software, integration can be more seamless. This also reduces your dependance on third party companies. The iPod, iTunes, iTunes Music store is an example of this control and integration.

- Average price of a Mac fell 7%

- 21% year over year growth in sales in higher education

- 11% growth in K-12

- 28 Million iPods sold with 248% revenue increase year over year

- 38 new brick and mortar retail stores were openned in 2005

- Retail sales almost doubled to $2.4 billion

- Research and Development increased (up 9%)

"To ensure the long term availability of adequate energy supplies, the BMW Group is committed to the principle of sustainable mobility, a concept that places emphasis on the efficient use of today's energy sources and the development of innovative solutions to meet future transportation needs. In order to reach this goal BMW Group further develops and enhances a variety of approaches, such as lightweight vehicle construction or the Valvetronic system which all help to decrease the consumption of carbon-based fuels.

Communication and information technologies give the automotive industry new opportunities for intelligent mobility in the future. BMW Group's ConnectedDrive networks telematics, online communication and driver assistance systems in order to enhance both safety and efficiency in transport. ConnectedDrive acts like a virtual co-driver presenting the right information at the right time, while still leaving the driver in total control. The active gas pedal, for example, "tells" the driver to slow down under specific conditions by exerting a greater counter-pressure against his foot. Intelligent route guidance taking even more detailed traffic information into account, helps to reduce road congestion and makes individual mobility more efficient in times of rapidly increasing vehicle numbers.

(Ranky: we use Dassault's Delmia, and other tools in this course...)

January 14

First Day of Sunday Classes

Monday

January 15

Martin Luther King's Birthday-No Classes Scheduled

Tuesday

January 16

First Day of Classes

Monday

January 22

Last Day to Add a Course

Tuesday

January 23

W grade posted for all Withdrawals

Monday

January 29

Last Day for a Refund based on a Partial Withdrawal

Tuesday

March 6

Last Day for a Refund based on a Complete Withdrawal

Monday-Sunday

March 12-18

Spring Recess-University Open-No Classes Scheduled

Monday

March 26

Last Day to Withdraw from Cours(s)

Monday

April 2

Summer & Fall Registration Begins

Friday

April 6

Good Friday-No Classes Scheduled

Saturday

April 7

Saturday Classes Meet

Sunday

April 8

Easter-No Classes Scheduled

Tuesday

May 1

Friday Schedule-Last Day of Class

Wednesday

May 2

Reading Day

Thursday-Wednesday

May 3-9

Final Exam Period

Thursday

May 10

Spring Grades Due in Registrar's Office

Thursday

May 17

Commencement (Tentative Date)

Project/ Assignment No. 2: QFD1 /CORA (Quality Function Deployment; Component Oriented Requirements / Needs Analysis) (20%)

Project/ Assignment No.4: Rapid Prototyping Study

Please rate the following topics planned to be covered in this class by rating each topic between 0 (not important / poor) and 10 (extremely important / excellent!) on the right hand side of the sheet please!

This feedback form will help your instructor to dynamically adjust the breath and the depth of the topics to be covered in this semester in this class to maximize your level of quality satisfaction.

Topics (as per the web-based syllabus) Your rating (0 -> 10)

Web-based syllabus (Rated: Very High)

eLearning Pack (Most students haven't seen it yet)

Introduction and overview of the course as well as the subject: Concurrent / Simultaneous Engineering (meaning exactly the same) in a traditional and in a modern design and manufacturing enterprise (Rated: Very High).

Object oriented (OO) process and enterprise models are introduced (Rated: High).

Systems and integrated processes are explained using traditional as well as new, OO methods (Rated: High)

Engineering management focus on how to find and reduce waste; how to support integrated product / process design concepts and models. (Rated: Very High)

Concurrent Engineering Methods, Tools and Technologies (Rated: Very High)

Process modeling the digital enterprise (Rated: Very High), with the exception of one: rated very low (2))

Focus on integrating design and manufacturing processes for the purpose of cutting waste, and improving quality (Rated: Very High)

Process modeling methods and examples (Rated: Very High)

Object Oriented Concurrent Engineering Information System Models (CIMpgr, Object Oriented Process Modeling is explained and discussed through exercises and examples) (Rated: Very High, with the exception of one, rated low (3))

QFD (Quality Function Deployment) (Rated: High)

Requirements Analysis is discussed with 3D Virtual Reality examples as an OO Concurrent Engineering methodology (Rated: Very High)

FMEA: The Failure Mode and Effect Analysis, or Process Failure Risk Analysis methodology and its use in CE (Rated: Very High, two rated it Medium)

Interactive FMEA modeling / Disassembly Failure Risk Analysis modeling with the 3D Virtual Reality examples on the DFRA CD-ROM (Rated: Very High)

Design For Manufacturing, Quality, Assembly (Rated: High)

KANRI, KAISEN, MUDA, MURA, MURI, POKA-YOKE (Rated: High, some did not know what this meant, so we are going to discuss it in detail)

The role of Quality Circles, and other methods discussed with 3D Virtual Reality examples and classroom exercises (Rated: High)

Rapid prototyping methods and solutions (Rated: most rated it Very High, nevertheless two rated it low (2-3))

Concurrent Engineering Team management methods and issues (Rated: Very High)

The TOPS method (The Ford Motor Company) (Rated: High, some did not know what this meant)

Virtual teaming methods over the Internet (Rated: High)

A 3D Virtual Reality web-based method and code is discussed in detail (Rated: most High, nevertheless two rated it Low (3))

Design For Environment and related Concurrent Engineering and CE Management issues, the way you see them related to the subject area of Hybrid cars (Rated: High)

Design of Experiments (DOE) Application Example, of YOUR choice, with the documentation and the calculations explained (Rated: High)

Industrial and R&D Case studies for every topic (as listed above) (Rated: Very High)

Any other topic you would like to cover? Please explain: (Received 4 requests)